Two vertical machining

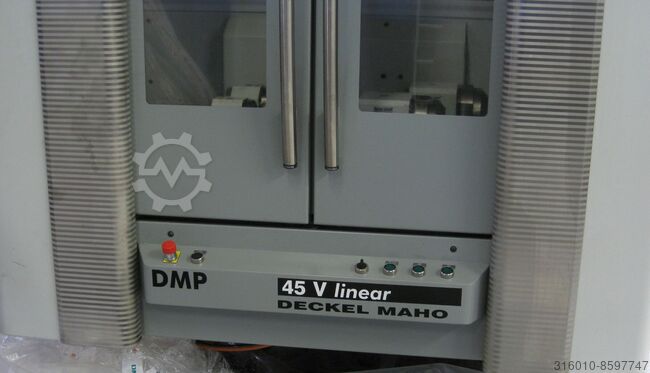

Two vertical machining centers from Deckel Maho’s special series will be sold:

A) Deckel Maho DMP 45 V linear High-End – 100% finished and ready for use after commissioning routine for longer service life.B) Deckel Maho DMP 45 V linear Basic – 100% mechanical / 95% electrical completed as parts dispenser or ready to be assembled.

Last modernized with parts in 2016 and maintained to date – few hours of operation.

Highlights:- unrivaled chip-to-chip time of 1.8 s thanks to modified double gripper principle (synchronized stroke and rotary motion)- guaranteed shortest tool change times- workpiece change in 3 s thanks to 180° swivel change table- generously dimensioned machine bed- compact machine design- highest precision and quality due to high rigidity and vibration stability thanks to moving column design- linear drive for maximum productivity

TECHNICAL DETAILS

travels X / Y / Z: 450 / 270 / 280 mmoption package 4th axis: NZ; dividing head and counter bearingCenter height: 130 mm from FTW (provided without servo motor)Accuracy: 0.008 mmfeed rate: 1 – 15.000 mm/minrapid traverse X / Y / Z: 80 / 72 / 72 m/min

Control: Siemens 840 D Powerlinetable: 2 pcs. 660 x 300 mmworkpiece weight: max. 200 kgtable change time: 3 s

spindle speed: 20 – 22.000 rpmtorque: 40,5 Nmtool holder: HSK-40Etool length: 180 mmchip-to-chip time: 1.8 s

MACHINE DETAILS

weight: approx. 6500 kginstallation dimension: 4065 x 3280 x 2466 mmtransport dimension: 4065 x 1845 x 2412 mm

Voltage: 400 V 3-phase / 230 V 50 HzVoltage control: 24 VPower consumption: 50 kVACompressed air: 6 bar

Cooling liquid: 200 lCooling flow rate : 40 l/minPressure: 2,5 barInternal cooling: IKZ through spindleInternal cooling liquid: 600 lInternal cooling flow rate: 23 l/minPressure: 40 bar

EQUIPMENT

1 table – divided into setup room side and work room side

IKZ unit INTERLIT 600 l

Chip conveyor

paper belt filter unit INTERLIT 600 l

Spare parts package worth 10.000 €; 2 x (part unit and counter bearing, spare motor spindle)