MEXPOL TUB 1030 Heavy Duty Lathe

turning diameter over bed: 1040 mm

turning diameter over support: 720 mm

centre distance: 5400 mm

center height over bed: 540 mm

control: Siemens 828D

turning dia. in gap: 1300 mm

length of gap: 640 mm

spindle bore: 152 mm

revolution per minute: 3,[…] 4 steps U/min

feed:: x-Achse: 37,24 (m/min) m/min

feed:: z-Achse: 21,91 (m/min) m/min

power feed longitudinal: x-Achse: 6,44 (KN) KN

feed capacity Z – max.: 17,2 (KN) KN

tailstock taper MT: MK 6

tailstock quill stroke: 300 mm

total power requirement: ca. 30 kW

weight of the machine ca.: 14,1 t

space requirement approx.:: L:7,7xB:1,7xH:2,0 m

CNC Lathe with shop turn

Geometric overhaul is in procedure.

Equipment:

– headstock Morse 6, travel of spindle sleeve 300mm

– thread cutting possible (metric thread, inch threads, module threads)

– multi quick steel holder swiveable 360°

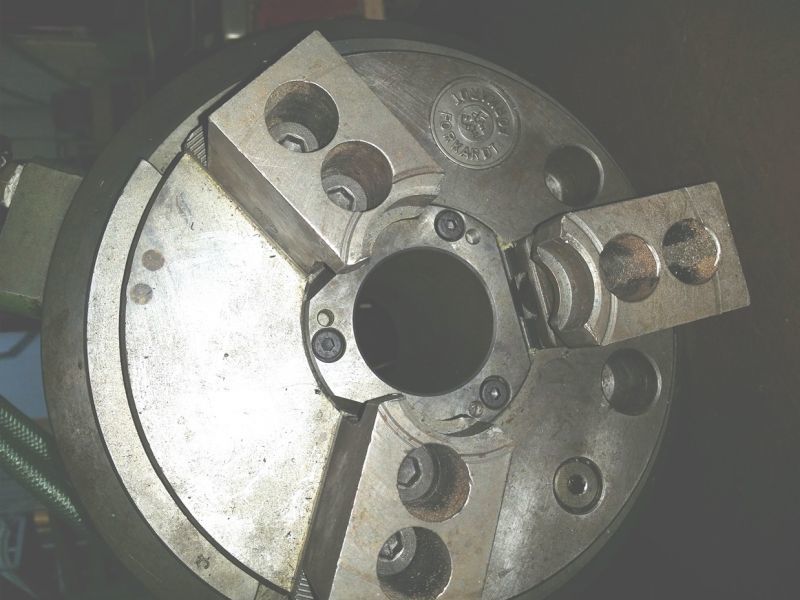

– 3-jaw lathe chuck Ø=630mm

– chuck protection

– 2 steady rests (Lynettes) (1x fixed + 1x fixed open)

– 4 pcs tips for tailstocks

– 5 x multi quick change steel holder for chisel

– 1 x drill chuck 16mm + 2x drills with MK-cone sleeves 68,5mm & 24,75mm

– 1 lot self constructed clamping means

Accessories:

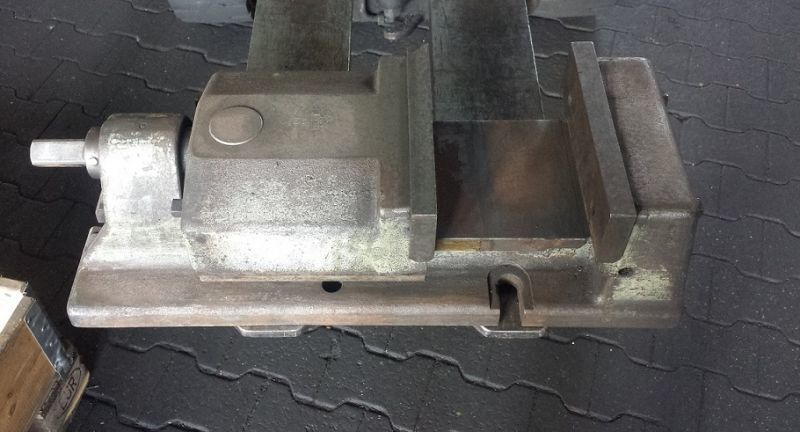

– face chuck Ø=800mm (adaptation necessary)

Bltuuhppa

– CNC turning with shop turn – your benefits at first glance:

– flexible programing via graphic interactive (without DIN/ISO knowledge) or text programming with contour definition and cycle support

– user friendly operation through practical set up -and measuring operations, clearly arranged tool managment and 3D-Simulation

– increase of productivity via supporting PC-Software for work preparation without machine assignment